My Kit Car Journey

/My kit car journey

When my love affair with the kit car industry started I had just qualified as an Engineer and was working at an electronics company in Suffolk way back in 1990. Whilst chatting with a colleague one afternoon he explained that he had a kit car in his garage which sparked my interest. That day I popped to his house after work and he took me out for a spin in his MG based NG TF. From that moment on I was sold on the kit car concept and started to do my homework. The kit car industry at the time was flourishing and there were a number of magazines providing loads of information for the home builder. There were also numerous companies, large and small offering a host of models from pocket rockets to big engine Cobra, GT40 and Lambo replicas, the choice was huge.

Initially I went to see Merlin and spent some time with Peter Gowling at his Essex based home and workshop. I really liked the look of the car but perhaps at that time I didn’t have quite enough money to do a decent job so wondered if there was anything similar out there that would better suit my limited budget.

I then went to Pilgrim to look at the Bulldog and met the unforgettable character that was Den Tanner, love him or hate him. This was a nice cheap option with classic looks based on the trusty old Ford Cortina. Once I had decided to bite the bullet and place an order with Den my young family started to come along so my kit car dreams got put on hold.

Work then took me around the country and abroad for a bit but in the mid 1990’s I settled in Hampshire and with finances a little more stable I started to look at kit options again. I was living in a lovely cottage just outside Hook and had ample space to embark on my delayed project.

On this occasion I had decided to go for something a little different and placed an order for a Robin Hood. That’s when I met another name from the past, the very astute Richard Stewart. The way in which he manufactured his little seven style cars was quite revolutionary, using state of the art laser cutting equipment to produce his chassis.

I was given a collection date and travelled up to Nottingham to join lots of other customers who lined up in the carpark with their vans and trailers. The way the kit was collected was fantastic. First there was a check to make sure you had paid for your kit and then you were given a trolley on which your chassis was mounted. You then made your way around the factory stopping at various points to collect the body panels, the lights and everything you had ordered. At the end of your little factory tour you went through your check list and off you went down the road with a full car in bits.

Initially the car was fitted with a standard Pinto engine but later on was upgraded to a 2.8 Cologne before it was eventually sold.

By now my fortunes had changed for the best and I was lucky enough to be running a small electronics company. I now started to troll through the pages in the two mainstream kit car magazines ‘which kit’ and ‘kit car’ but this time my sights were set a bit higher and I was now in the market for a Cobra.

I had two trains of thought, either go for a Dax or something similar and possibly not be able to have all the shinny bits or go for a cheaper model but be able to afford all the options. I visited a number of suppliers and eventually ended up back at Pilgrim placing an order for a Ford Sierra based Sumo. By now though Den had moved on and I was dealing with Tony Ward who I have to say was brilliant throughout. I bought the kit along with a Chevy V8 engine, Tremec gearbox, a donor package and all the trim including leather seats Etc. As I hadn’t splashed out as much as I would have done if I had gone for one of the bigger cars I was able to get the chassis galvanised and all the suspension completely refurbished with new parts all round. The car was finished in a lovely BMW blue colour and I had a number of years of fun with it. The car was amazing and although I wasn’t sat behind the wheel of a Dax, GD or AK this didn’t detract from my enjoyment. I think that is one of the great things that has always been around in the kit car industry. There was always something for every one and something to suit different budgets. It’s true to say that back then however, there were some awful, and possibly dangerous home built cars out there but the introduction of the SVA and later the IVA seemed to up the quality. This scared some away and companies were charging premiums for SVA compatible packages but once everybody had got their head around the new test things seemed to calm down.

My Cobra then got sold on as my business started to struggle and I had to devote a lot more time and money to keeping things going.

The business eventually crashed when a big chunk of the electronics industry, along with a lot of my customers took advantage of attractive overseas alternatives to UK manufacturing.

Although I kept track of the market over the years I didn’t get involved directly until recent years when I sold a house and had some money back in my pocket. This time when I looked around the industry had sadly shrunk and when I attended a few kit car shows it was apparent that lots of companies had gone and even the big guns had changed hands and appeared to be struggling to secure orders. Prices had also risen and the choice of model availability was limited.

I wasn’t sure whether to take on a full kit car package or go for something that I hadn’t seen before, a rebody project and in particular something based on the tried and tested BMW Z3. The idea of a reliable car with decent engine options as a single donor seemed a really clever idea. Fortunately for us another character in recent kit car history, Richard Bird from Nubodi was based just up the road from us near Reading. I visited Nubodi with my now 20 year old youngest mechanic son Ben to check things out. We looked at the Cobra but weren’t sold so settled on the model that has now been modified and become known as the Isabella. The build was relatively easy and with a BMW mechanic in the house things went very smoothly. During the build process we spent quite a lot of time with Richard and actually ended up building a Cobra as well. It was then that we found that Richard was planning to retire to France and an opportunity to pick up where he left off arose.

It was now that we met Chris at Tribute Automotive who actually manufactured and supplied a range of rebody kits. I remember the day we turned up at his Dorset workshop explaining that we were taking over from Nubodi. His face was a picture but after setting out some ground rules we were now the proud agents for Tribute and Classic Coachworks was born. Our small company consisted of myself, Belinda and up until recently my youngest son, Ben. We had already set ourselves up in a small workshop on the A303 near Andover and in addition to selling parts and kits we also started to offer a build service. Things soon took off and we outgrow our workshop in no time at all. We looked around and eventually found our current workshop which is based in a beautiful country park near Basingstoke. We have a fully set up work shop and a number of demonstrators on site. In addition to the kit car business we also support the BMW Z3 market by providing spare parts and services to keep as many of the little cars on the road as possible. We did think that we would get grief from the ranks of Z3 fans as we were destroying their cars but it actually worked the other way and we are always happy to support the Z3 community, attending the AV8 meets when possible. We get some strange looks when we turn up in our creations but that is all part of the fun.

Over the past couple of years we have tried to attend as many shows as possible to promote our little business but we are very small and it’s not always possible. If we can’t get to a show we always welcome customers to our workshop. I’m rubbish at remembering to buy milk so the tea isn’t always up to scratch. If people are planning a visit always give us some notice as that gives me a chance to pop to the shop on the way.

This piece has been quite positive throughout and I am so happy that we have travelled on this journey but I have to say things have been quite difficult for us along the way, not only financially. Rising costs for industrial premises and material costs almost doubling have proved hard to manage. I would love to say that our little operational always pays well and I’ll be buying a villa in Spain but the sad truth is that isn’t the case. Thankfully we still do things outside Classic Coachworks and that supplements what we do.

The kit car industry is not what it was and fewer and fewer companies seem to be fighting for their chunk of the market. The price for a decent kit now has risen but there are still bargains out there.

Also, an industry based on copying is always going to create its own problems. We have noticed that there is always someone out there trying to buy a kit so they can copy it so you have to keep your wits about you. We have experienced that ourselves but luckily enough we have weathered the storm.

Our business is based on not only the selling of kits and parts but also building cars and making customer dreams come true. This is harder than it sounds as goal posts often move as the build progresses. Finances can often slow down and in our experience part built cars can sit in the workshop for longer than we would like for various reasons. With Brexit, Covid and the cost of living crisis having an impact on most people in some way or another money can get tight and people’s priorities understandably change. We have always been happy to help where possible by spreading costs and housing customer cars but that is not always easy. We only have limited space and have in the past had to move things around so that we can continue to operate efficiently.

One area which is specific to what we do and can cause problems relates to donor vehicles. As our kits are body conversions rather than conventional kit cars which are built from the ground up they retain all the features of the original car. On the whole customers purchase decent donor cars and this makes things easier but there are also customers who are on a strict budget and purchase the cheapest donor possible happy in the knowledge that the car when complete will look fine. I always tell customers that the final project is still only as good as the car underneath so it can be a false economy going for the cheaper option. My advice would be to purchase the best donor you can afford with as many options as possible i.e. sports seats, air conditioning, cruise control Etc. There is quite a market out there for used BMW Z3 parts so the cost of a kit or build could be offset against the sale of the unused parts including wing mirrors, body panels and trim.

I think we have come a long way in a short period of time and have definitely made mistakes and been naive along the way but it has been, and continues to be a positive and rewarding experience although we rarely get a break. We still have daft projects that we have purchased that will never get off the ground but I think that’s quite common in this line of work. “One day Rodney”. Of course we occasionally buy the odd kit car to refurbish and sell on or just to run around in. Even when it’s raining and the doors and roof leak it’s much more fun to drive to work in an old kit car than a boring modern box on wheels. I’ll probably regret it when the Winter months hit. I recently sold two Merlins and currently have a little Tiger Six which is so much fun.

So looking to the future things look ok for us and the industry. I attended the Malvern kit car show at the start of 2023 and the huge line of Westfields shows us that there is still a kit car scene to be proud of in this country. We have also heard positive things from the magazines and show organisers so I am confident.

Looking ahead for us I guess that social media is the key. When my eldest son started producing TikTok videos I had no idea what was happening to the world but I soon realised that this is probably the way to go. We haven’t ventured into dance videos yet but we do use other social media sites and Belinda has been working hard to get this off the ground and increase our online presence.

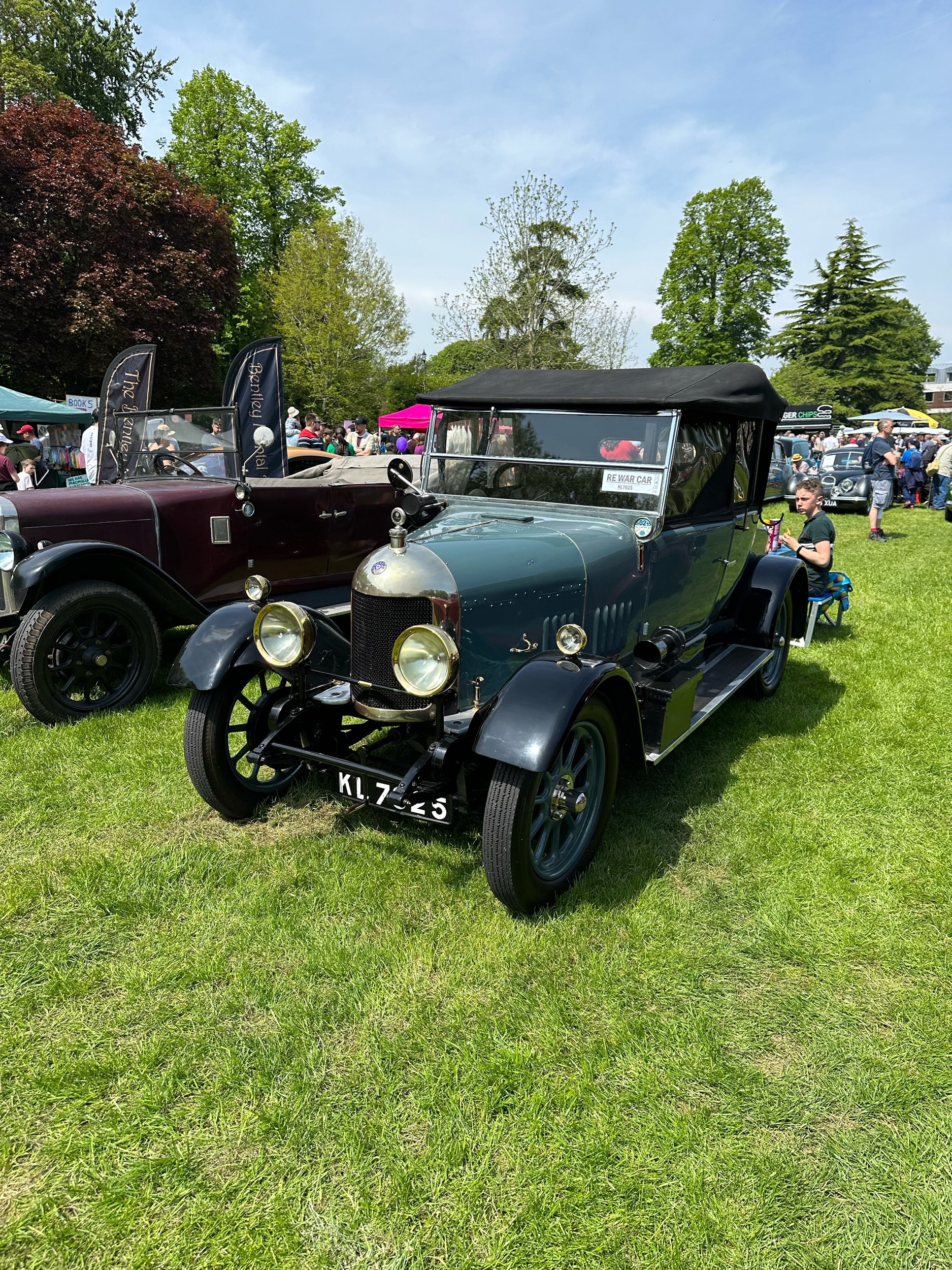

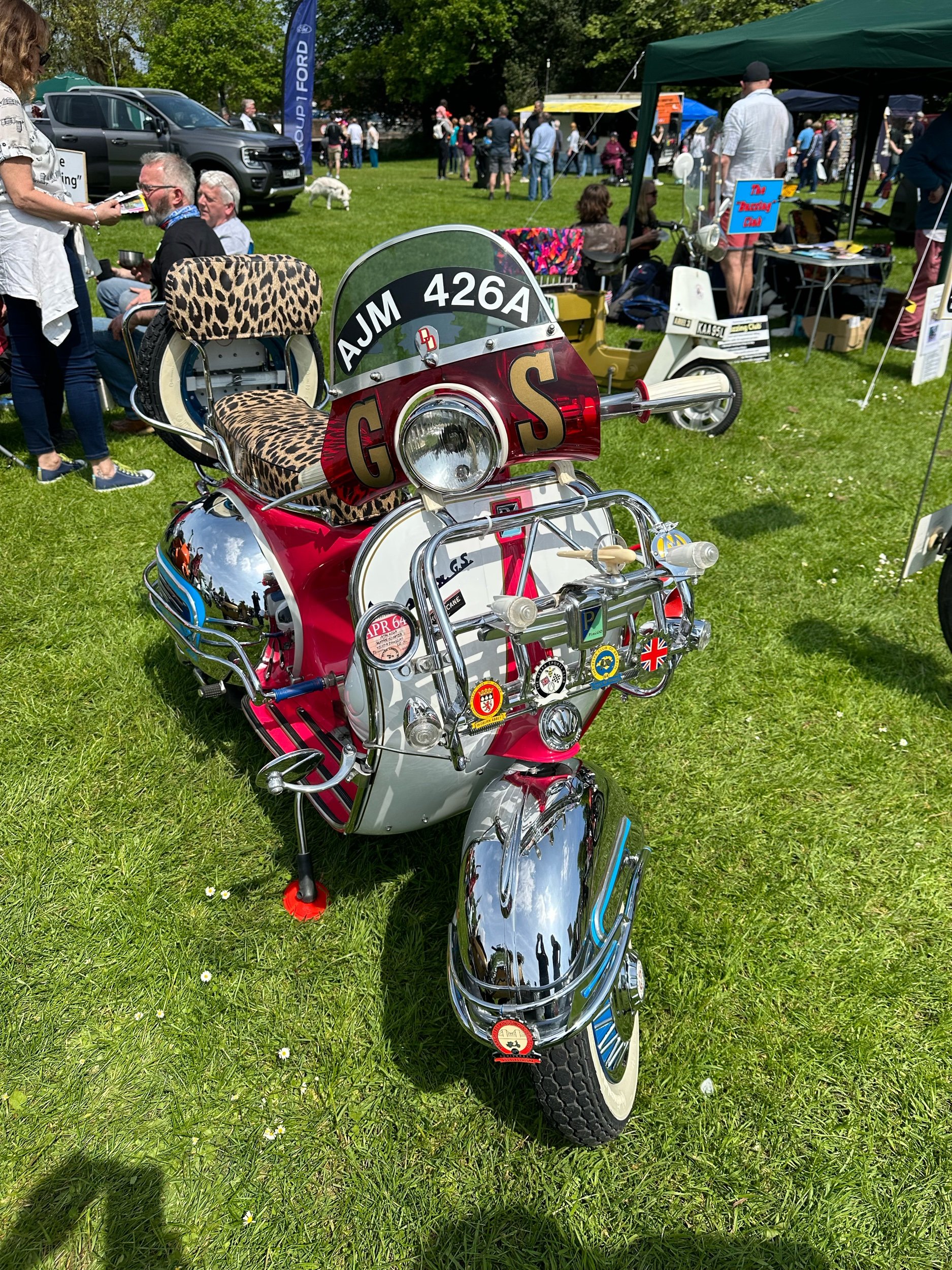

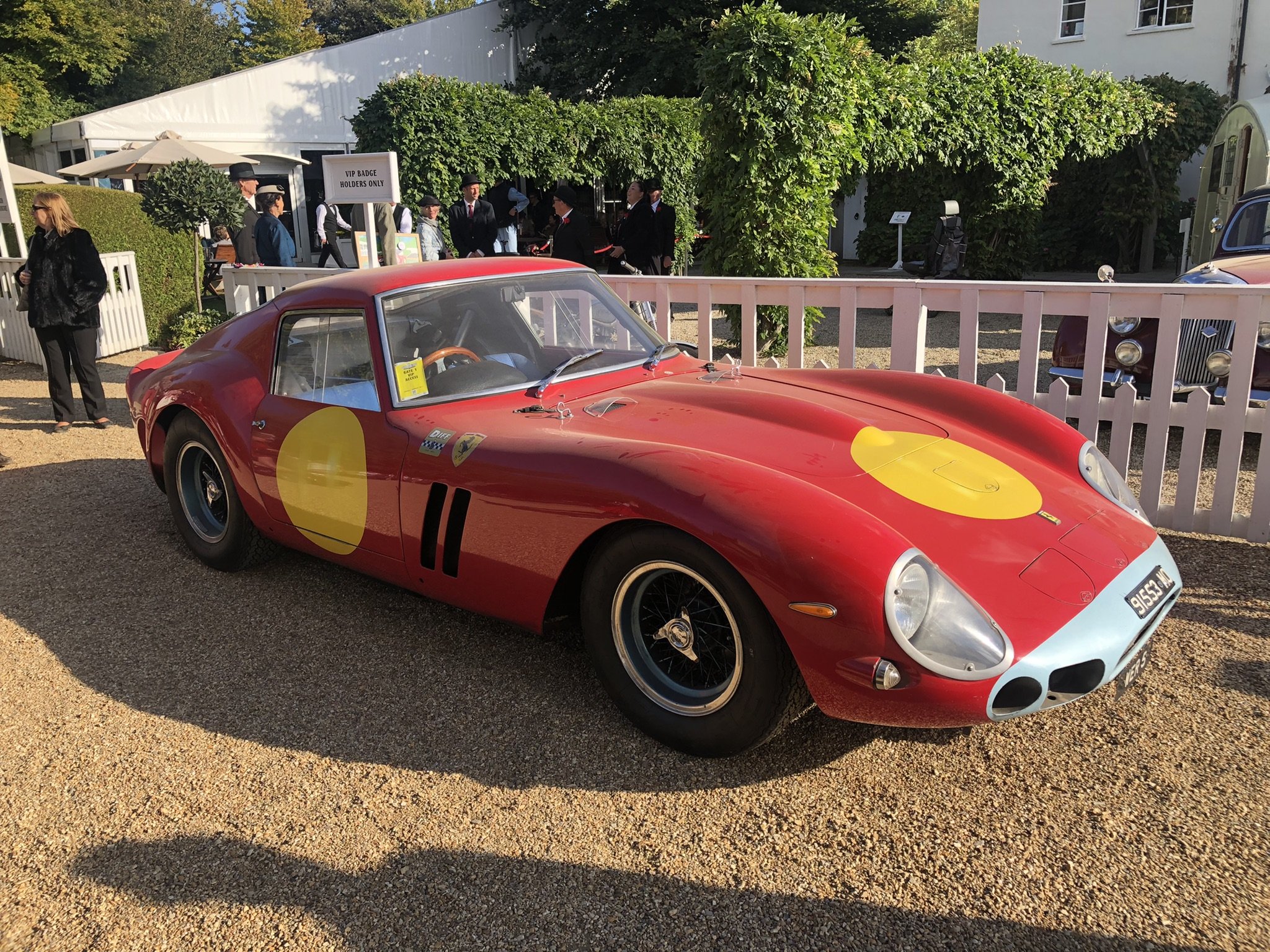

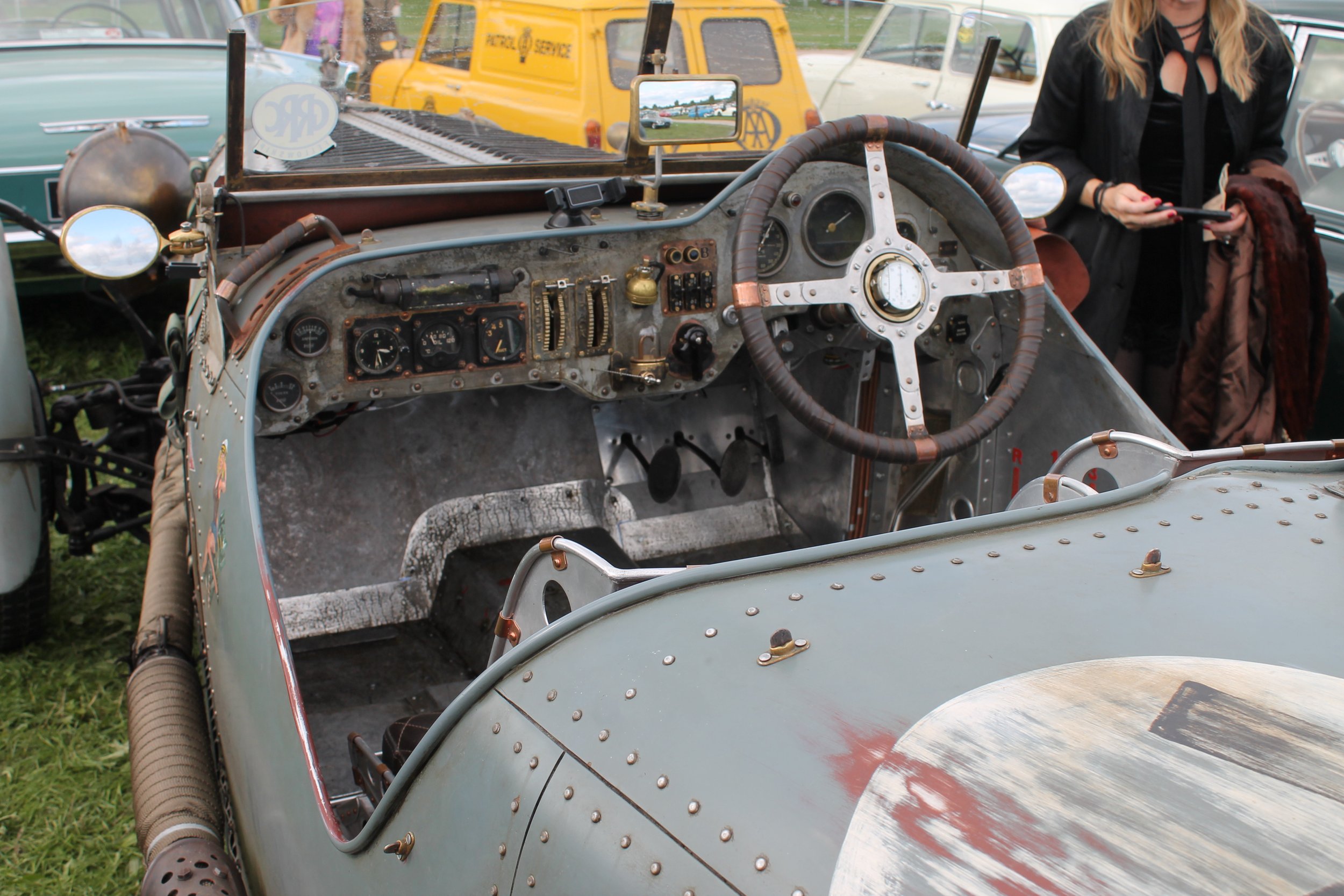

Through the contacts and the relationships she has forged we have become involved with the guys who organise the British Motor Show and along the way have met some amazing people who all love our cars. These included TV personalities, online influencers and some of the royalty of the motorsport industry. It has been a whirlwind tour and rounded off with us in Lord March’s enclosure rubbing shoulders with the rich and famous at Goodwood revival which was amazing.

We are not really at home in such company but anyone who moves in these circles knows that they are normal people at the end of the day and if we get a kit sale then we are happy.

When all is said and done I am looking forward to the future and hoping that we can grace a few of the kit car shows in 2024. We will definitely be at the Festival of Transport in Basingstoke, the British Motor Show and anything else we can get to.

Apart from thanking the guys who have printed my dribble I would like to thank Chris at Tribute for his continued support along with BC Racing, Powerflex and of course the team at Europa.

Ian Castle